Solvent Emission News & Solutions for the Printing Industry

July 26, 2016 4:52 pmSolvent Emission News & Solutions for the Printing Industry

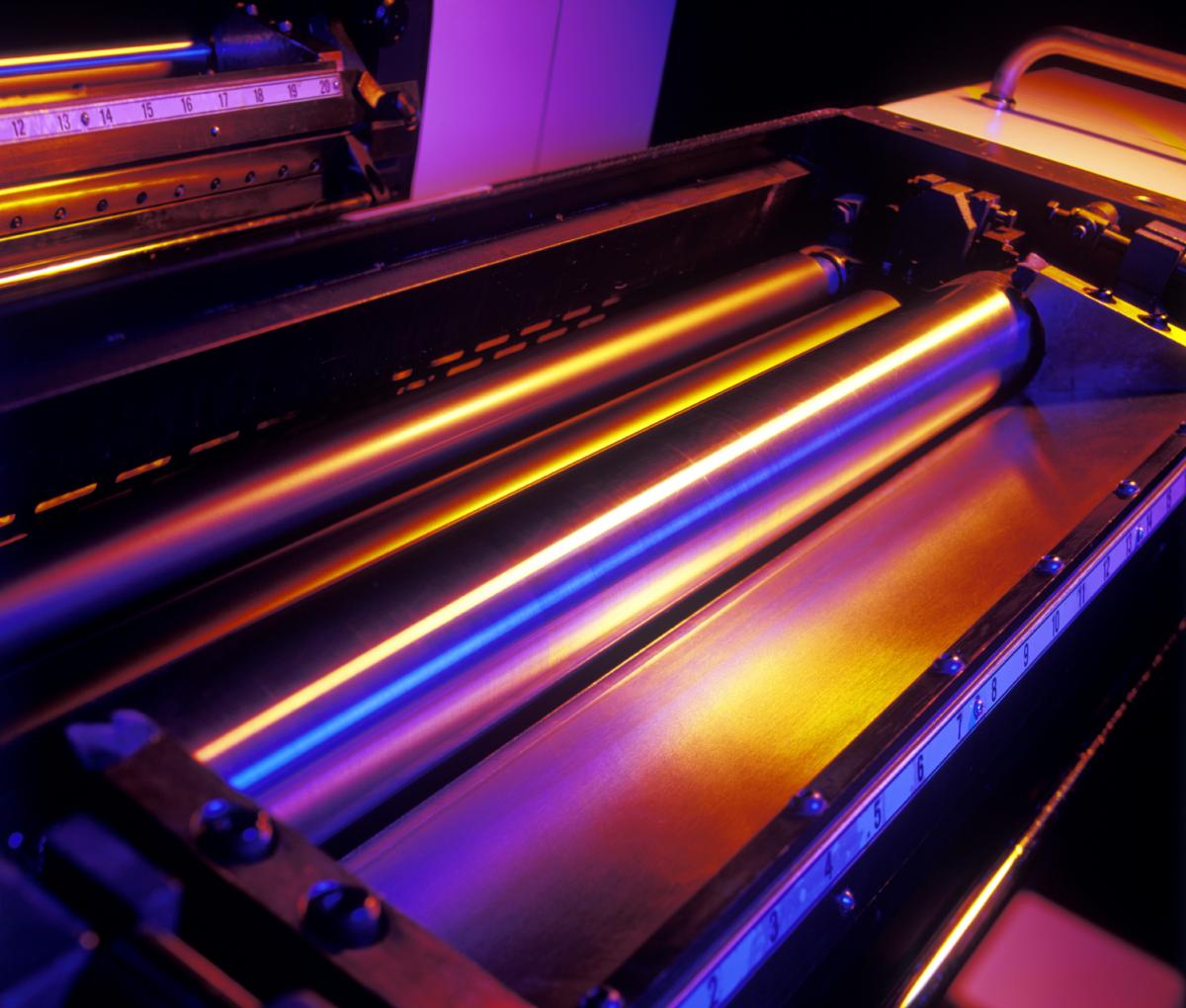

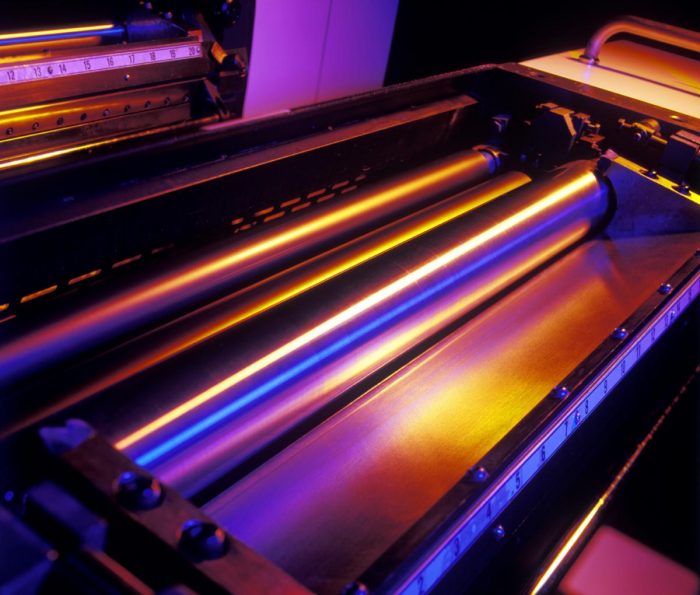

Emissions from printing operations result primarily from evaporation of organic solvents contained in the inks. Most of the solvent contained in the ink evaporates during the process, although some solvent may remain with the printed product leaving the facility. The organic solvents used in the ink may be Volatile Organic Compounds (VOC) or Hazardous Air Pollutants (HAP). Some inks may be water-based and do not produce emissions.

Ship & Shore specializes in providing air pollution abatement equipment for the printing industry and has thousand of successful systems operating globally that meet both compliance and performance demands.

Ship & Shore 60,000scfm RTO for Packaging Application

In general, the emissions points from a printing line (operation) include the: 1) ink fountain, 2) the press, 3) the drier, and 4) the chill rolls [actual emissions points vary by the type of printing operation]. Typically, a large fraction of the emissions are associated with exhausts from ink in the drying units (drier). Driers typically use natural gas or electricity to heat air. The warmed air passes over the substrate in the drier, causing the volatile compounds in the ink on the substrate to evaporate. The drier exhaust air containing the volatilized solvents is contained in a duct and the air stream is vented to the atmosphere; the air stream may be directed to an air pollution control device (APCD) prior to venting to the atmosphere.

The most advanced and cost effective technology is a S&S Clean Tech Regenerative Thermal Oxidizer for emission of the common VOCs found in most printing applications.

Ship & Shore 45,000 scfm Regenerative Thermal Oxidizer

Emissions that are not collected and routed to a duct or stack are called fugitive emissions. Fugitive emissions can come from several sources in a printing operation, such as ink feeding systems and the chill rolls. Vapor capture systems (e.g., ventilation hoods, floor sweeps, or enclosures) may be used to capture, contain, and exhaust the emissions from these sources (to an air pollution control device), thereby reducing the amount of fugitive emissions. The printing equipment may include vapor capture systems as part of the design and operation of the equipment.

Other sources of fugitive emissions include ancillary operations such as press washing (cleaning) and ink mixing operations. Air emissions from imaging include potential volatile components in the developer (e.g. alcohol) and fixer. Adhesives used in finishing operations such as laminating also may contain VOC and HAP and are a potential source of emissions.

Ship & Shore also designs and fabricates Permanent Total Enclosures PTEs for 100% VOC Capture of fugitive emissions associated with printing operations and helps maintain a safe working environment for workers.

Ship & Shore Custom Design 100% Capture PTE

Printing industry pollution is predominantly released into the air. In 1993, the printing industry released 99 percent of its total Toxic Release Inventory (TRI) poundage to the air, while the remaining one percent of releases were split between water and land disposal. The four top toxic chemicals released, toluene, methyl ethyl ketone, xylene, and 1,1,1-trichloroethane, are all solvents of high volatility. By far the single largest toxic chemical used (released/transferred) by the printing industry is the solvent toluene; toluene comprises roughly 70 percent of the total chemicals released and transferred by the industry (in 1993). Toluene is used heavily in the gravure printing process as an ink solvent, but is also used throughout printing for cleaning purposes.

To learn more about the EPA standards for the printing industry please read full article by clicking here.

Ship & Shore helps manufacturers maintain compliance with complete environmental solutions for air pollution abatement and energy and heat recovery systems for maximum efficiency and cost effective operations. Call or Email us today to see how current and coming regulations may affect your manufacturing application. Your project may be eligible for significant cash incentives from energy efficiency programs! Call 562.997.0233 or EMAIL us by clicking here.

Categorised in: Air pollution, EPA, News, News, Technical, Uncategorized