Aftermarket Essentials

Ship & Shore’s Engineering and Technical Team custom engineer and design each system specific to the industry, application, and air quality rules and regulations of each client. Familiarize yourself with the tips, tricks, and aftermarket updates to ensure optimum system performance.

Upgrades & Retrofits

Upgrades & Retrofits

Ship & Shore offers retrofit designs and upgrades to improve equipment performance and profitability with several aftermarket solutions.

More PM Inspection

PM Inspection

To ensure your oxidizer is operating at peak and optimum performance, schedule annual Preventive Maintenance (PM) Inspections.

More Waste Heat Recovery

Waste Heat Recovery

S&SE has the expertise and experience to custom design waste heat recovery systems capable of re-directing process exhaust.

More Spare Parts

Spare Parts

We can provide a checklist of spare parts to ensure performance and compliance helping you minimize downtime.

MoreThe ownership of air pollution control equipment goes beyond recognizing your air pollution control equipment is still running. The critical components of thermal oxidizers are not visible at first glance and the lack of internal/overall inspection of your unit may lead to costly downtimes and nuisance shutdowns. Our team of trained technicians have years of experience servicing all brands of oxidizers and can provide a wide variety of aftermarket services.

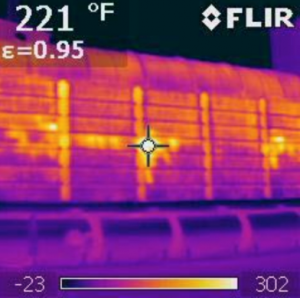

THERMAL INSULATION AND INSPECTION

Damages of the internal insulation of a thermal oxidizer can be detected early if frequent thermal imaging of your equipment is done. A thermal image allows you to see where damages of internal insulation may lead to overheating or failure of the thermal oxidizer shell. Hot spots at the surface of your unit indicate where overheating and possible warping of the sheet metal may occur. Hot spots are not visible to the human eye but are necessary to be replaced before they cause real damage. Not repairing damages early enough can lead to shut downs and serious loss of production.

Thermal Image

Hot Spot on RTO shell

Internal Hot Spot

CERAMIC MEDIA INSPECTION & ENERGY EFFICIENCY

Ship & Shore Regenerative Thermal Oxidizers (RTOs) are equipped with ceramic heat exchanger media. Media can be ceramic saddles or structural media blocks. Without performing an annual internal PM Inspection of your thermal oxidizer, you may find that your media is plugged up or damaged, creating a pressure drop across your oxidizer chambers.

Example of plugged ceramic saddle HX media

Example of plugged honeycomb HX media

For Inspection, repairs and other aftermaket services, call (562) 997-0233 or email service@shipandshore.com